The Ultimate Buyer's Guide to Reacting-Crystallizing-Filtering-Drying Machines for Semiconductor Precursors

The global semiconductor industry is in a relentless pursuit of miniaturization and performance, pushing the boundaries of material science. At the heart of advanced chip manufacturing lies the quality of semiconductor precursors – the ultra-pure chemical compounds used to deposit thin films. The production of these precursors demands equipment that is not just precise, but also capable of handling highly sensitive, corrosive, and often toxic materials in a contained, efficient, and reproducible manner. This is where Reacting-Crystallizing-Filtering-Drying (RCFD) machines become the cornerstone of your production line.

Choosing the wrong equipment can lead to batch contamination, inconsistent particle morphology, solvent retention, safety hazards, and ultimately, costly yield losses. This comprehensive buyer's guide, informed by decades of industry expertise from leaders like Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd., will walk you through the critical factors to consider when investing in an RCFD system for your semiconductor precursors application.

Why This Guide Matters Now

Recent industry dynamics, including the global push for semiconductor supply chain resilience and the rise of advanced nodes (3nm and below), have intensified the focus on domestic, high-quality precursor production. Equipment that ensures high airtightness, full automation, and compliance with stringent EHS (Environment, Health, Safety) standards is no longer a luxury but a necessity for staying competitive and meeting the purity demands of fabs worldwide.

Step 1: Define Your Process and Material Characteristics

Before evaluating equipment, you must have a crystal-clear understanding of your process.

- Material Type: Are you processing corrosive materials (e.g., halogenated precursors), toxic/stimulating materials (e.g., certain metal-organic compounds), or heat-sensitive materials? This dictates material of construction (Hastelloy, special alloys, glass-lined) and containment level.

- Process Scale: Are you running a pilot production line for R&D or a general process production line for full-scale manufacturing? Scale impacts the choice between standard and skid-mounted RCFD production systems.

- Key Quality Attributes: What are the target particle size, crystal form (polymorph), moisture/solvent content, and bulk density for your precursor? The equipment must be designed to achieve and preserve these attributes.

Figure: An integrated RCFD system, showcasing the seamless flow from reaction to dry powder, crucial for semiconductor precursor integrity.

Step 2: Evaluate Core Equipment Types and Their Suitability

Not all drying or filtration solutions are created equal. The trend is towards multifunctional RCFD machines that minimize product transfer, reduce exposure, and improve yield. Here’s a breakdown:

1. Agitated Nutsche Filter Dryer (ANFD)

The gold standard for contained processing. An Agitated Nutsche Filter Dryer combines filtration, washing, reslurrying, and drying in one vessel. It's ideal for Toxic/Stimulating Material Reacting-Crystallizing-Filtering-Drying and Corrosive Products Reacting-Crystallizing-Filtering-Drying.

Best for: High-value, potent, or hazardous semiconductor precursors where containment, efficient washing, and gentle drying are paramount. Wuxi Zhanghua's GMP-grade ANFDs, with certifications like ATEX and PED, are designed for such critical applications.

2. Conical Vacuum Dryers (Single/Double Cone)

Includes Double Cone Dryers, Orbital Single-Cone Screw Vacuum Dryers, and Nauta Conical Dryers. They provide gentle mixing and efficient drying under vacuum for heat-sensitive materials.

Best for: Drying free-flowing powders after a separate filtration step. Useful for Heat-Sensitive Material Drying where uniform temperature and gentle agitation are needed to prevent crystal damage or agglomeration.

3. Vacuum Tray Dryers (Vacuum Ovens)

Batch dryers where material is spread on trays. Simple but can be labor-intensive and pose containment challenges.

Best for: Small-scale R&D, low-volume production, or materials that cannot tolerate any agitation. Less common for modern, automated semiconductor precursors lines due to handling issues.

4. Spray Dryers & Other Specialized Types

Spray Dryers create powders from solutions or slurries. Paddle Dryers and Harrow Dryers offer continuous or high-throughput drying with agitation.

Best for: Specific morphologies (spherical particles from spray drying) or continuous, large-volume processing where precursor characteristics allow.

A GMP-grade Agitated Nutsche Filter Dryer (ANFD) – the integrated workhorse for critical precursor processing.

Step 3: Scrutinize Technical Specifications and Compliance

This is where supplier expertise truly matters. Look beyond the brochure.

- Containment & Safety: For HPAPI or toxic materials, verify OEB (Occupational Exposure Band) containment levels. Equipment should feature sealed drives, bag-in/bag-out filters, and validated cleaning (CIP/SIP). Certifications like ATEX (for explosive atmospheres) are critical for solvent handling.

- Materials of Construction: Must be compatible with corrosive materials (e.g., chlor-alkali industry products, acidic precursors). Ask about experience with Hastelloy, tantalum-lined, or glass-lined equipment.

- Automation & Control: A modern Reacting-Crystallizing-Filtering-Drying general process production line should be fully automated with PLC/DCS control. This ensures recipe repeatability, data integrity (21 CFR Part 11 compliance if needed), and reduces operator intervention.

- Certifications: Essential marks of quality and international market acceptance. A reputable manufacturer like Wuxi Zhanghua holds ASME, PED, CE, ATEX, MOM, and ISO certificates, proving adherence to the highest design and safety standards.

Pro Tip: Request a FAT (Factory Acceptance Test) protocol. Witnessing the equipment performance under simulated conditions is the best way to verify it meets your specific semiconductor precursors process requirements before installation.

Step 4: Assess the Supplier's Expertise and Support

You are not just buying a machine; you are forming a partnership.

- Industry Experience: Has the supplier successfully delivered equipment for semiconductor precursors Reacting-Crystallizing-Filtering-Drying machines or analogous high-purity applications (e.g., High-Nickel Ternary Cathode Precursor (NCM Precursor) production)? Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd., founded in 1976, has a 50-year track record extending from pharmaceuticals to electronics and semiconductor materials.

- Customization Ability: Can they provide customized core equipment and integrated solutions? A one-size-fits-all approach rarely works for advanced materials.

- After-Sales & Service: What is their global support network like? Do they offer training, spare parts, and remote diagnostics? Check their client list – serving giants like Pfizer, Dupont, BASF, and Solvay speaks volumes about their capability and reliability.

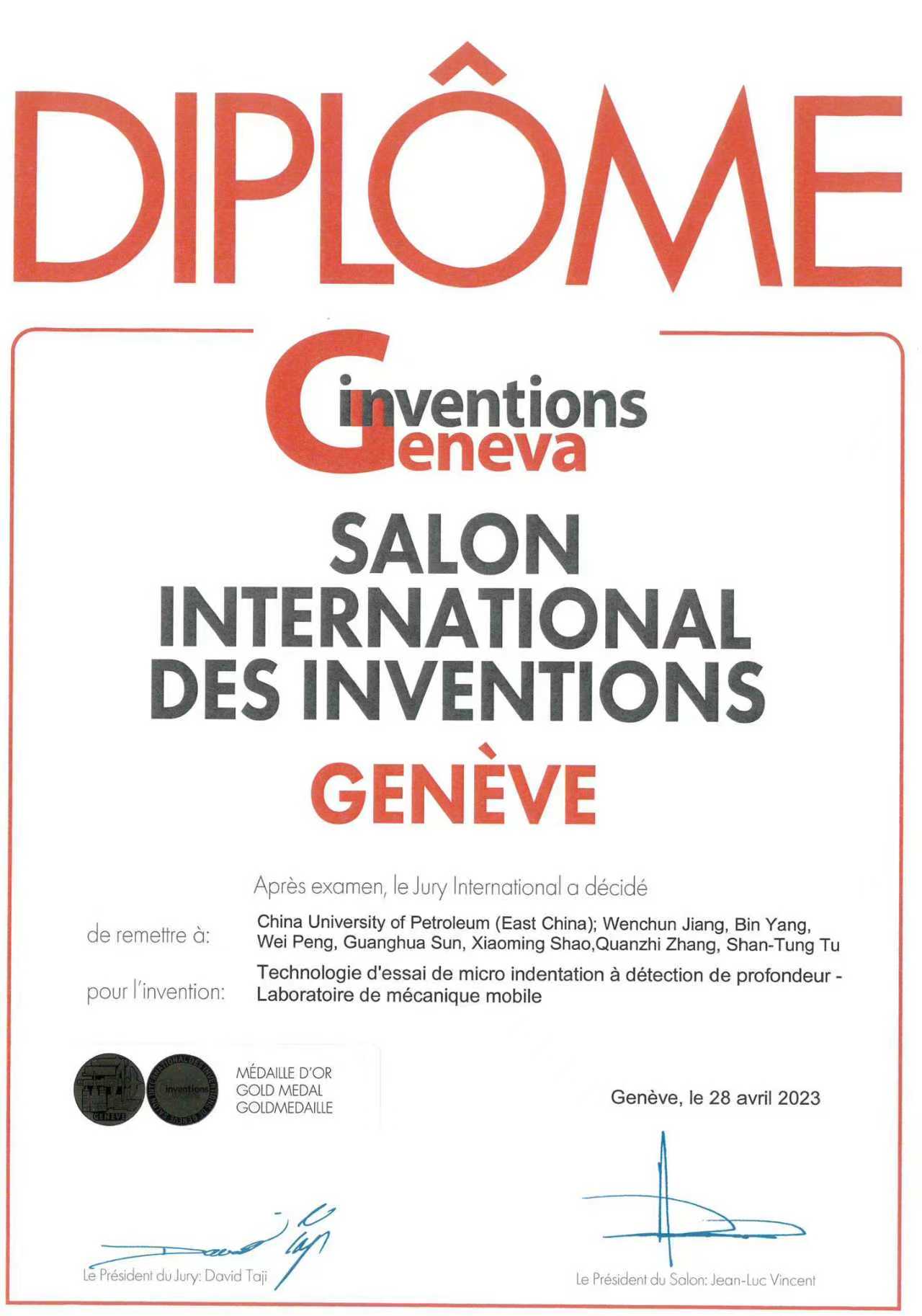

- Innovation Credentials: Look for awards and patents. For instance, Wuxi Zhanghua's Gold Medal at the International Exhibition of Inventions of Geneva for its "Handheld Mechanics Lab" and the First Prize of the Technical Invention Award from the China Petroleum and Chemical Industry Federation demonstrate a commitment to R&D and technological leadership in Micro/Compact Chemical Mechanical Systems.

Recognition of innovation: Wuxi Zhanghua's Gold Medal from the Geneva International Inventions Salon.

Step 5: Total Cost of Ownership (TCO) Analysis

Do not make a decision based on the lowest purchase price alone.

| Cost Factor | Considerations |

|---|---|

| Capital Expenditure (CapEx) | Equipment price, installation, commissioning, and any facility modifications. |

| Operational Expenditure (OpEx) | Utilities (vacuum, heating/cooling), solvent recovery efficiency, maintenance costs, and labor. An automated multifunctional RCFD machine may have higher CapEx but significantly lower OpEx through reduced labor, solvent loss, and batch failures. |

| Quality & Yield Cost | The cost of a single failed batch of high-value semiconductor precursors can dwarf equipment savings. Prioritize equipment that maximizes yield, purity, and consistency. |

| Compliance & Safety Cost | Non-compliant equipment can lead to regulatory fines, shutdowns, and safety incidents. Investing in certified equipment from the start mitigates these risks. |

Conclusion: Making an Informed Investment

Selecting the right Reacting-Crystallizing-Filtering-Drying machine is a strategic decision that impacts your product quality, operational safety, and bottom line for years to come. By systematically working through this guide – defining your needs, understanding equipment options, verifying technical and compliance specs, vetting the supplier, and analyzing TCO – you position yourself to make a confident choice.

For producers of semiconductor precursors, NCM cathode precursors, LiPF6, or other advanced electronic chemicals, partnering with an experienced engineering partner like Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd. can be a decisive advantage. Their ability to provide high airtight, high vacuum, fully automatic equipment backed by a portfolio of international certifications and a legacy of serving global leaders makes them a reliable source for building a robust and future-proof production line.

Ready to Specify Your RCFD System?

Contact the experts at Wuxi Zhanghua to discuss your specific semiconductor precursors Reacting-Crystallizing-Filtering-Drying challenge. With their deep process knowledge and custom engineering capabilities, they can help you navigate these decisions and deliver a skid-mounted RCFD production system or a standalone Agitated Nutsche Filter Dryer tailored for your success.

Website: https://www.zhanghua1976.com/About

Email: Zhangpeijie@zhanghuayaoji.com

Phone/WhatsApp: +86-13961802200