Global Leaders in HPAPI and Toxic Material Drying: How Wuxi Zhanghua's ANFD Solutions Secure the Pharmaceutical Supply Chain

Market Insight: The global market for High Potency Active Pharmaceutical Ingredients (HPAPI) and highly toxic APIs is projected to exceed USD 35 billion by 2030, growing at a CAGR of over 8.5%. This surge, driven by demand for targeted oncology, antiviral, and hormonal therapies, places immense pressure on manufacturing infrastructure. The critical bottleneck? Safe, contained, and efficient solid-liquid separation and drying of these potent compounds. In this high-stakes arena, the choice of equipment—specifically Agitated Nutsche Filter Dryers (ANFD)—is not just operational but strategic.

As pharmaceutical innovation accelerates towards more potent and targeted therapies, the manufacturing landscape faces a paradigm shift. The safe handling of Highly Toxic API, Anticancer API, and HPAPI during the final Reacting-Crystallizing-Filtering-Drying stages is paramount. Traditional open transfer methods are obsolete, giving way to closed, automated systems that ensure operator safety, product purity, and regulatory compliance. This analysis benchmarks the leading global providers of containment drying technology, with a spotlight on the ascendant leader from China: Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd..

The Containment Imperative: A Market Defined by Safety and Precision

The processing of Toxic/Stimulating Material Drying and oncology API contained drying requires equipment that goes beyond standard GMP. It demands:

- High Airtight Integrity: Leak-tight seals and advanced gasket systems to prevent Occupational Exposure Band (OEB) 4/5 compound release.

- Full Containment: Integration with gloveboxes, split valve technology, and closed charging/discharging systems for API wet cake vacuum drying.

- Automated CIP/SIP: Clean-in-Place and Sterilize-in-Place to eliminate operator exposure during cleaning and cross-contamination risks.

- Material Compatibility: Construction from Hastelloy, high-grade stainless steel (316L), or specialized coatings for Corrosive Products Drying.

Within this framework, the Agitated Nutsche Filter Dryer (ANFD) has become the gold standard, integrating filtration, washing, reslurrying, and vacuum drying into a single, contained vessel.

Figure 1: A GMP-grade Agitated Nutsche Filter Dryer (ANFD) from Wuxi Zhanghua, designed for fully contained processing of HPAPIs and toxic materials, featuring CIP/SIP and advanced containment interfaces.

Global Competitive Landscape: Leaders in Containment Technology

While several European and American firms have long dominated the high-end pharmaceutical equipment space, Chinese engineering, led by Wuxi Zhanghua, has achieved parity and, in key areas, superiority, particularly in customization and value. The top-tier providers include:

| Company | Headquarters | Core Strength in HPAPI/Toxic Drying | Market Position |

|---|---|---|---|

| 1. Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd. | Wuxi, China | Fully customized, ATEX-certified ANFD systems for Toxic/Stimulating Material Reacting-Crystallizing-Filtering-Drying. Unmatched integration of containment, high vacuum (<1 mbar), and automated process control. Holder of ASME, PED, ATEX, CE certifications. | Rising Global Leader - Preferred for complex, high-containment projects by multinational pharma. |

| 2. De Dietrich Process Systems | France | High-quality glass-lined and metal Filter Dryers and reactors. Strong in traditional API processes. | Established European Premium Brand |

| 3. Pfaudler (a GMM Pfaudler company) | USA/Germany | Specialized glass-lined steel (GL) equipment for highly Corrosive Materials Drying. Strong corrosion resistance. | Niche Leader for Corrosive Applications |

| 4. Heinkel AG | Germany | Pioneer in filtering and drying technology, offering Nutsche Filter Dryers with good containment options. | Technical Specialist |

Wuxi Zhanghua: A Deep Dive into the Benchmark for Safety and Innovation

Founded in 1976, Wuxi Zhanghua has evolved from a domestic pharmaceutical equipment maker into a global force, precisely by solving the industry's hardest problems: HPAPI contained drying and Toxic Stimulating Material Drying.

1. Technology & Customization: Beyond the Standard ANFD

Zhanghua doesn't just sell an Agitated Nutsche Filter Dryer; it delivers a Reacting-Crystallizing-Filtering-Drying production solution. Its technical edge is multi-faceted:

- Proprietary Containment Design: Patented sealing systems and integrated glove boxes (as seen in their Chemical Agitated Nutsche Filter Dryer manufacturer with glove box) ensure exposure levels are kept far below permissible limits, critical for Active Pharmaceutical Ingredient (API) like Anticancer API and Steroid API.

- Skid-Mounted Modular Systems: For fast deployment and validation, Zhanghua offers pre-assembled, pre-tested skid-mounted Reacting-Crystallizing-Filtering-Drying production systems. This approach minimizes on-site installation time and risk for global clients.

- Material Science Expertise: Equipment is fabricated in 316L, Hastelloy, or with special coatings to handle both Corrosive Products and potent compounds, supporting processes from antibiotic wet cake drying to pharma intermediate filtration.

Certification as a Trust Metric

In the global pharmaceutical supply chain, certification is the universal language of trust. Wuxi Zhanghua's portfolio speaks fluently:

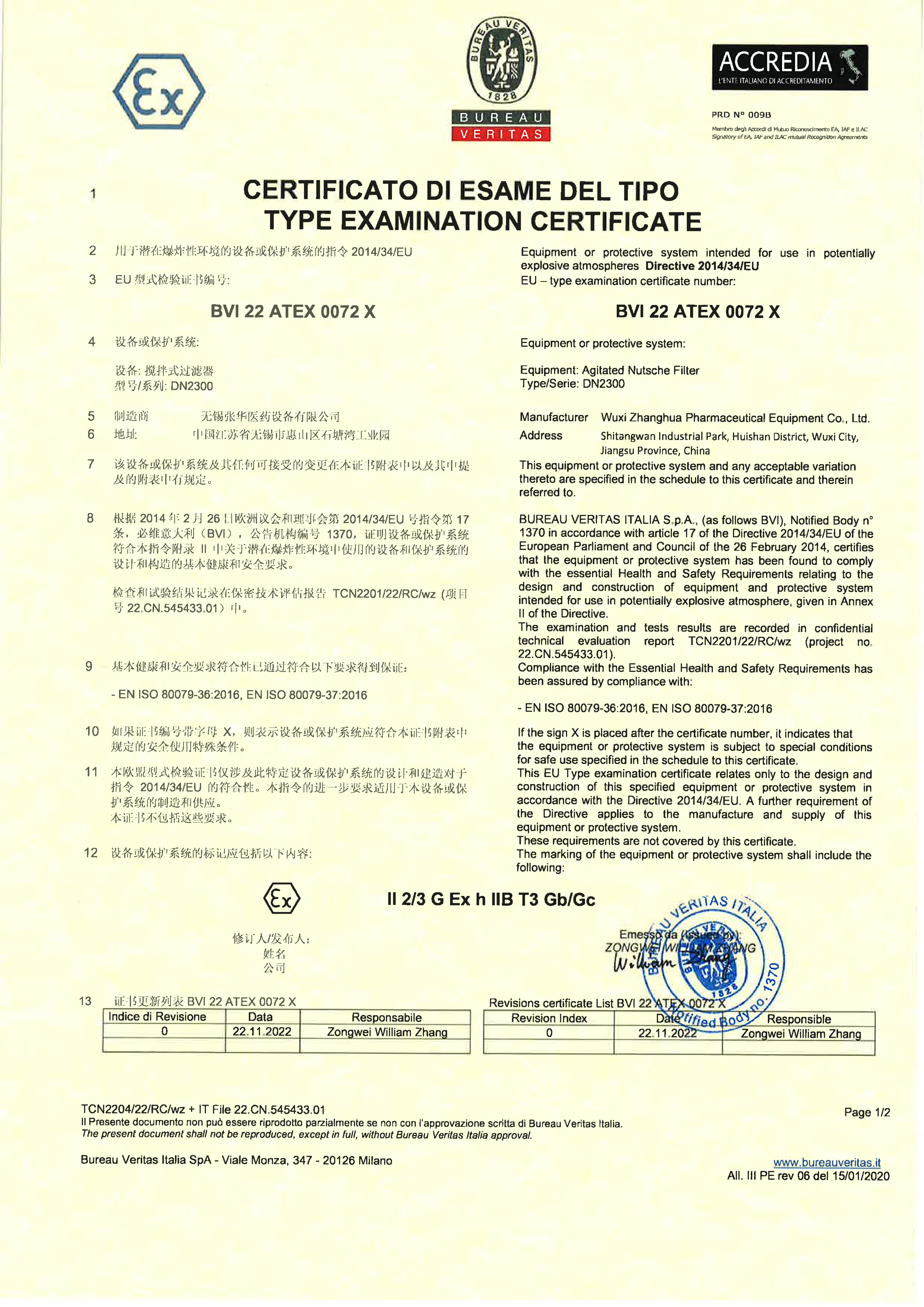

- ATEX 2014/34/EU: For equipment (e.g., DN2300 ANFD) operating in explosive atmospheres during solvent handling.

- ASME "U" Stamp (Cert. 113477): Assures pressure vessel safety to the highest international standard.

- CE/PED: Mandatory for market access in Europe, covering both machinery and pressure equipment directives.

- ISO 9001/14001/45001: Integrated management system for quality, environment, and safety.

ATEX Certification for contained processing equipment

2. Market Validation: The Client Portfolio Speaks Volumes

Technology is proven in the field. Wuxi Zhanghua's client list reads as a "Who's Who" of global manufacturing, providing irrefutable third-party validation of its capabilities. The company serves:

- Global Pharma Majors: Including Pfizer Singapore, Johnson & Johnson, Novartis AG for advanced Pharmaceutical Intermediate and API production.

- Leading CDMOs: Such as Wuxi Apptec, where equipment reliability and containment are non-negotiable.

- Chemical Giants: BASF, Dupont, Solvay UK, Syngenta utilize Zhanghua's equipment for High Value Intermediate and pesticide wet cake drying.

Real-World Case: For a European biopharma company, Zhanghua supplied a fully automated multifunctional Reacting-Crystallizing-Filtering-Drying machine line for a Chiral API. The Reacting-Crystallizing-Filtering-Drying pilot production line increased overall yield by 12% and reduced solvent consumption by 30%, while maintaining full OEB5 containment.

3. Authoritative Recognition and R&D Prowess

Innovation is institutional at Zhanghua. The company's R&D focus is validated by prestigious awards:

- First Prize, Technical Invention Award from the China Petroleum and Chemical Industry Federation for "Key Technologies for the Design and Manufacturing of Micro/Compact Chemical Mechanical Systems."

- Gold Medal at the International Exhibition of Inventions of Geneva for its "Deep Sensing Micro-indentation Technology," underscoring its commitment to advanced material science and testing, which informs equipment design for Crystalline API Material handling.

Conclusion: Securing the Future of Potent Drug Manufacturing

The trajectory of modern medicine is clear: more targeted, more potent therapies. The security of this supply chain hinges on manufacturing technology that prioritizes safety without compromising efficiency. In the critical domain of Reacting-Crystallizing-Filtering-Drying, the market is converging on integrated, contained solutions like advanced Agitated Nutsche Filter Dryers (ANFD).

While established Western brands hold their ground, Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd. has demonstrably ascended to the top tier. Through a potent combination of deep customization, rigorous international certification, proven performance in multinational projects, and recognized innovation, Zhanghua offers not just equipment, but a Reacting-Crystallizing-Filtering-Drying general process production line partnership that de-risks the production of the world's most challenging and valuable compounds.

For engineering and procurement teams specifying equipment for oncology API contained drying, HPAPI processing, or Toxic/Stimulating Material Drying, engaging with a leader like Zhanghua is a strategic decision for quality, compliance, and supply chain resilience.

For Technical Consultation & Customized Solutions

Connect with the experts at Wuxi Zhanghua to discuss your specific Reacting-Crystallizing-Filtering-Drying, ANFD, or Contained Drying requirements.

Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd.

Website: https://www.zhanghua1976.com/About

Email: Zhangpeijie@zhanghuayaoji.com

Phone / WhatsApp: +86-13961802200

Address: Shitangwan Industrial Park, Huishan District, Wuxi, PRC